SUSTAINABILITY

Accountable for environment, business, and stakeholders.

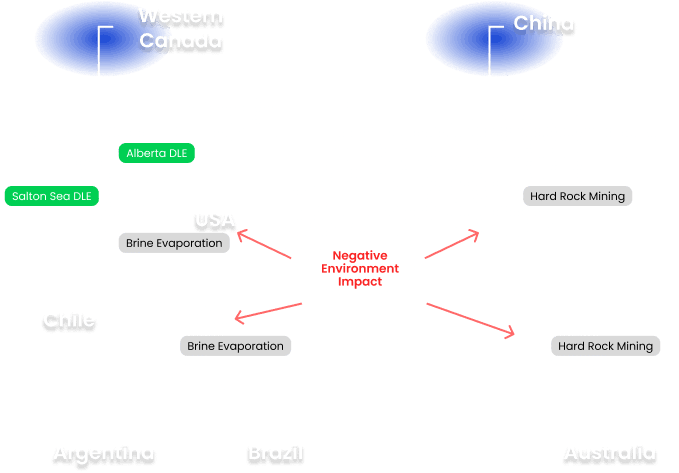

Willcox Energy seek to develop, build and operate lithium facilities that adhere to the highest standards of environmental monitoring, compliance and reporting, while producing future sources of high-quality, low-cost lithium compounds to fuel a global, low-carbon economy.